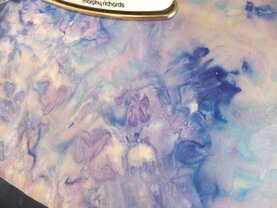

Salt Patterned Silk Scarf By Jane Cameron I wrote this tutorial for Creative Crafting Magazine back in 2013, so I think it's about time I shared it with you! Make your own gorgeous intricately patterned silk scarf to wear in this fabulous summer weather! You will need:

(Silk painting supplies available from www.silkcraft.co.uk – use the code GUILD1 at checkout for a discount on your first order)

If you want to find out more about the art and craft of silk painting, visit www.janecameron.co.uk and www.silkpainters-guild.co.uk. Jane Cameron runs silk painting courses in Woking, Surrey and is a member of the Guild of Silk Painters. © Jane Cameron 2013. Instructions are for personal and educational use only. Please get in touch if you'd like to use this tutorial with your students or your art group.

0 Comments

The scarves you all helped to paint at Crafting Live Sandown are now safely out of the steamer. I have also managed to get hold of a second copy of the Silk Painting book. Now that's done, I'll draw the winners ...

SATURDAY SCARF: Amanda G SATURDAY BOOK: Shirley T SUNDAY SCARF: Lynda A SUNDAY BOOK: Annabelle TW Thank you to Search Press for the copies of the Silk Painting book by Mandy Southan. If you missed out, you can get your copy here: https://www.searchpress.com/book/9781782212102/beginner-s-guide-to-silk-painting Congratulations to the winners! I'll be in touch with you by email to get your postal addresses :D Just one more day at Crafting Live Sandown, we're open 10-4 on Sunday. Looking forward to seeing loads of you there! It's always so lovely to catch up with my previous students, and with my colleagues on other stands too.

We had a fantastic response to our "help us paint a scarf" yesterday, and have a fresh one outlined ready for today, so please do come and have a go! My colleague Delva (pictured) and I look forward to meeting you :) I've had to print out a load more course schedules, as I ran out and had to ask people to take photos of my one remaining printout (which I taped to the table!!!). Thank you so much for all your interest, and I look forward to seeing you on one of my courses soon. A shout out to my friends the lovely Nancy over at Flights of Fantasy - really excited you're going to be demoing at RHS Garden Wisley in May - and to Amanda Hill Glass Artist - amazing to meet you at last! Oh, and Rainbow Silks - we've been recommending you to people, so hope you get some new customers! Also silkcraft.co.uk and mulberry silks FREEBIE JANUARY 2019

Free tickets to Crafting Live at Sandown Park, Esher, Surrey UK Free tickets to Crafting Live at Sandown Park, Esher, Surrey UK CLOSING DATE 1000pm WEDNESDAY 23rd JANUARY Thanks to the lovely people at Crafting Live, I have 10 e-tickets to give away for this show, which is on Saturday and Sunday 26-27 January 2019. I'll be demonstrating silk painting on stand G6, as part of the Guild of Silk Painters. Do come and say hello and help me to paint a big silk scarf! To enter, please email jane@janecameron.co.uk with the subject line "FREEBIE JANUARY 2019". Please state whether you would like one or two tickets. Please state that you are happy for your email address to be passed to Crafting Live if you are successful in your application for tickets. If you missed out, you can buy tickets for this show here: www.craftinglive.co.uk/shows/sandown/ TERMS: There are 10 e-tickets available. The tickets are valid for either day of the show. The first 10 valid entries to be received (or 5 if pairs of tickets are requested) will receive the tickets. My decision is final. This prize has no monetary value. Your email address will be provided to Crafting Live, who will send you your e-ticket(s). They will not use your email address for any other purpose and will delete it after use. Happy New Year!

I've got loads of exciting things happening in January - I'm running a silk painting individual masterclass, a beginners workshop (private group) and I'm also demonstrating silk painting at Crafting Live at Sandown Park on 26-27 January. Come and see me and my colleagues on the Guild of Silk Painters stand G6, and help me paint a big silk scarf! New course dates: 16th March - Silk Painting for Beginners / Improvers 30th March - Inspired by Klimt 18th May - Silk Painting for Beginners / Improvers 22nd June - Silk Painting for Beginners / Improvers I only take 4 students on each course, so you get loads of individual attention and technical assistance, working on your own choice of subject to achieve your potential. Want a custom silk painting day for you and your friends? Get in touch! Shows: 26-27th January - Crafting Live at Sandown Park 8th June - Thread at Farnham Maltings (TBC) Thanks to the lovely people at Search Press for sending me a copy of this book for review. I have not been paid for this review and my opinions are my own.

Link to book is here, RRP £8.99 "With 3 colours, 3 brushes and this practical advice, you can start painting watercolour landscapes" The techniques in this book can also easily be applied to "free" silk painting projects. If you're looking to experiment with anti-fusant, or "magic sizing" or even spray starch or saturated salt solution, then this is a great book on painting landscapes. The instructions of how to build up a landscape, how to blend and merge colours, how to mix all the shades and tints, and painting different textures are well explained. You could outline some foreground elements with outliner and then use these techniques for the background, or start by building up a freeform landscape and then embellish over the top. Definitely a helpful book if you're getting into landscapes. Just remember that you'll need to put some sort of "anti-spread" on your silk (or work with a super-dry brush on thicker silk) if you're hoping to get the clarity of line you can get on paper. A good resource. Thanks to the lovely people at Search Press for sending me a copy of this book for review. I have not been paid for this review and my opinions are my own.

This is a review of the 2003 edition of this book. There is also a more modern edition. The book can be accessed here: CLICK I've always been fascinated by Indigo dyeing, but mainly bought this book to improve my repertoire of Shibori (tie-dye!) techniques. It's got a section of 22 pages all about the different Shibori methods, and it's brilliant! Nice clear pictures, so many clothes pegs! It even has instructions for how to use a pleating machine (now I want one!) but remember that the folds won't stay in if you wash it later! I've tried quite a few of these techniques over the years, and have even used them for microwave dyeing with silk! If you're into indigo, then it's also got recipes for two different dye vats, and a list of projects including a "Bog Jacket" (one piece of fabric, two seams ... sounds like my kind of sewing project!). Thanks to the lovely people at Search Press for sending me a copy of this book for review. I have not been paid for this review and my opinions are my own.

Take Silk A Guide to Silk 'Paper' for the Creative Fibre Artist by Judith Pinnell Here's the link to the book *click here*, RRP £10.99 "This book will take the reader into a world of colour, creativity and an exciting new dimension in textile art. The textile worker will learn how to make their own substrate - 'paper' using many decorative techniques. Both traditional and hand embroiderers will find plenty to interest them sufficiently to want to experiment using rich threads and other accessories to create two- and three-dimensional pieces that are completely original. If you love the colour and richness of silk, then this is the book for you." Take Silk, by Judith Pinnell, isn't quite my sort of book. You can make loads of exciting textures, but I found that the process was a bit too much like felting (too much hard work for me!) for it to really be of interest to me. I have made paper (in a blender!) so am not a total novice to paper making, but I think I'd prefer to make things out of actual silk or actual paper. There are some fantastic projects in there, but I prefer my silk to be able to move, and a lot of the projects are structural which isn't really my style. If it's yours, then you'll love this book! Thanks to the lovely people at Search Press for sending me a copy of this book for review. I have not been paid for this review and my opinions are my own.

"Rosi Robinson shows how to create beautiful batik designs and pictures, teaching all the techniques required through 9 gorgeous projects. From making simple marks and drawing with wax to dipping and painting with dyes, etching cracking, discharging and more, this book contains all you need to create beautiful batik." Book link here RRP £9.95 This is a surprisingly chunky-feeling softback book, at 96 pages, made of solid glossy paper. Lots of colour illustrations. This book covers the use of Procion MX cold water fibre-reactive dyes, but the techniques could be applied to other dyes also. This book covers the "silk painting" style of Batik, and also has a section on using "solid wax" like wax crayons to produce designs on the paper or fabric. There's a bit on covering the entire piece of fabric with wax and then scratching off your design! There's also a section on using the brush, and a section on stamping, which is great as you can see several examples of the applications of each technique. I thought that this book was well set out, and the use of "wax as outliner" to make silk painting style pieces would appeal to those who may have trouble squeezing an outliner bottle. This book has definitely earned a permanent place in my library, and I look forward to trying some of the techniques to create my own projects. Just a little note to let you know that I'm having a short break from running silk painting courses so I can undertake some essential home maintenance.

Please join my mailing list to be the first to find out when my new courses are available to book. I look forward to seeing you soon! Silk scarves, silk painting kits and other delights are available to purchase by personal customers by appointment - please get in touch! |

Jane Cameron

Experienced silk painter, glass fuser, teacher, enthusiastic and inspirational. Archives

June 2019

Categories |

RSS Feed

RSS Feed